Are you having trouble quilting on your own and require a quilting frame? If yes, then you should get a quilting frame. A quilting frame is essentially a solid structure that holds the quilt while you work on it comfortably. While they may be expensive, you can always build your own with the right kind of material.

In this guide, we will cover extensive and step-by-step details on how to make your own quilting frame at home.

Before starting work on your quilting frame, it is essential that you decide on the size you want to build. The size of your quilting frame should be enough to accommodate the specifications of the quilt you want to make.

You can build your frame in any size, whether for mid-arm or long-arm quilting

Trusted Source Longarm quilting - Wikipedia Longarm quilting is the process by which a longarm sewing machine is used to sew together a quilt top, quilt batting and quilt backing into a finished quilt. The longarm sewing machine frame typically ranges from 10 feet (about 3 meters) to 14 feet (about 4.25 meters) in length. A complete longarming system typically consists of an industrial length sewing machine head (19 – 30 inches,) a 10 to 14-foot frame, a table with a layer of plastic under which is placed a pantograph, and several rollers on which the fabric layers and batting are attached. en.wikipedia.org

, as long as you ensure that the length of your canvas is less than the length of your frame. This gives room for the backing fabric to be attached to the frame with clamps while you are quilting.

Following are some standard lengths for quilting frames:

| Frame Length | Canvas Length |

| 8 ft | 84 inches |

| 10 ft | 108 inches |

| 12 ft | 132 inches |

| 14 ft | 156 inches |

Each frame length translates to a different quilt size, for example, a 10-feet frame can be used for a queen size quilt, or a 12-feet frame can be used for a large king-sized quilt.

The size of the frame depends on the kind of quilt you want to make. Once you have decided the size of your frame, you can get started!

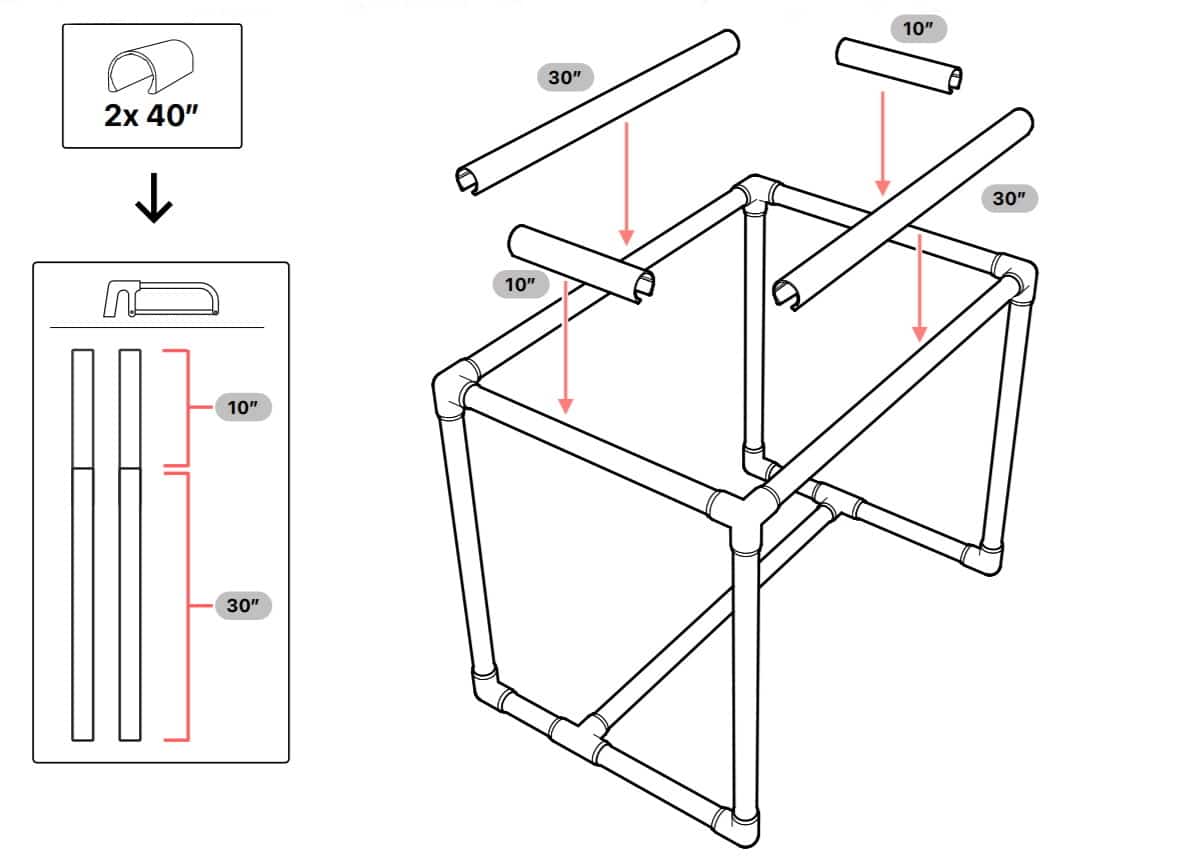

One way to make a quilting frame is by using PVC pipes. While you can find PVC quilting frames easily in the market, it is just as easy to make it on your own. PVC frames are ideal for tying quilts or for detailed quilting.

Here is how you can make one:

The first thing you would need to do is to gather all the materials required to make the frame. For this purpose, you would need PVC

Trusted Source Polyvinyl chloride - Wikipedia Polyvinyl chloride (colloquial: polyvinyl, vinyl; abbreviated: PVC) is the world’s third-most widely produced synthetic plastic polymer (after polyethylene and polypropylene). PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible. en.wikipedia.org

pipes. We recommend this pipe. PVC pipes are not only easy to store but their lightweight design helps you make a portable quilting frame. If you want to build a larger quilting frame, you can use CPVC.

Apart from the pipes, you would also need 3-way elbow fittings as well as pipe snap clamps.

You can buy snap clamps in different sizes; we recommend the 1-inch or the 1.25-inch clamps.

The next thing you need to do is to make sure that you have all the necessary tools to build this quilting frame. For this project, you need to have:

All of these supplies can be easily bought from any local hardware store or you can even order them online.

After gathering all the necessary material and tools, it’s time to get started:

Step 1: First thing you need to do is to cut the PVC pipes according to your required size. For this purpose, use a measuring tape and mark down your desired lengths. Once you are done, you can use a pipe cutter to start cutting. After cutting the pipes, smooth out the edges with sandpaper to ensure smooth assembly.

Step 2: Next up, you have the assembly part of the process. Using the 3-way elbow fittings, attach all your pieces together. For maximum stability, you can also use PVC glue between the pipe and the fittings.

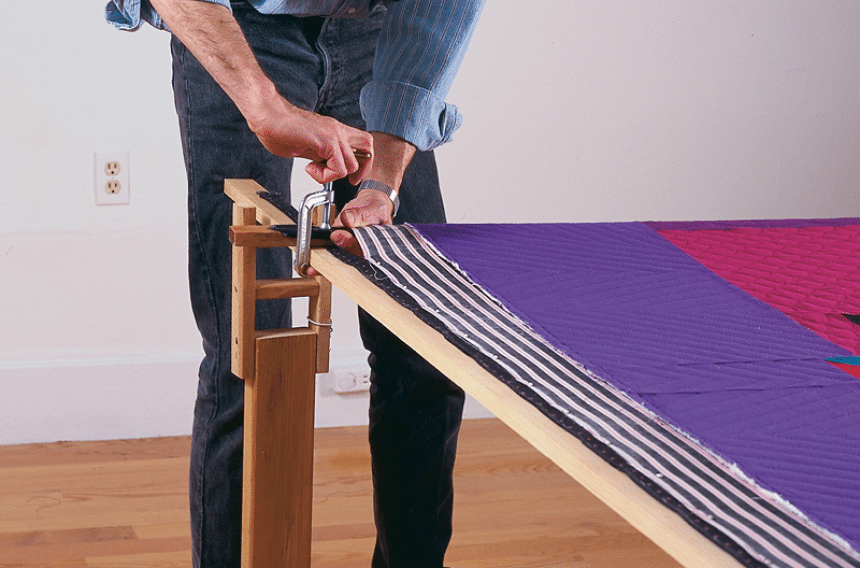

Step 3: After attaching the pipes, you can attach your fabric to the frame using snap clamps. Depending on the thickness of your fabric, you can use all kinds of snap clamps. While attaching snap clamps, make sure you are following safety precautions so your hand remains safe.

Step 4: Once your frame is ready, you can start quilting. For mechanical methods, you can always use a long arm quilting machine. These machines are compatible with quilting frames and can make your life easy while quilting. If you have a small frame, you can always opt for mid-arm quilting machines.

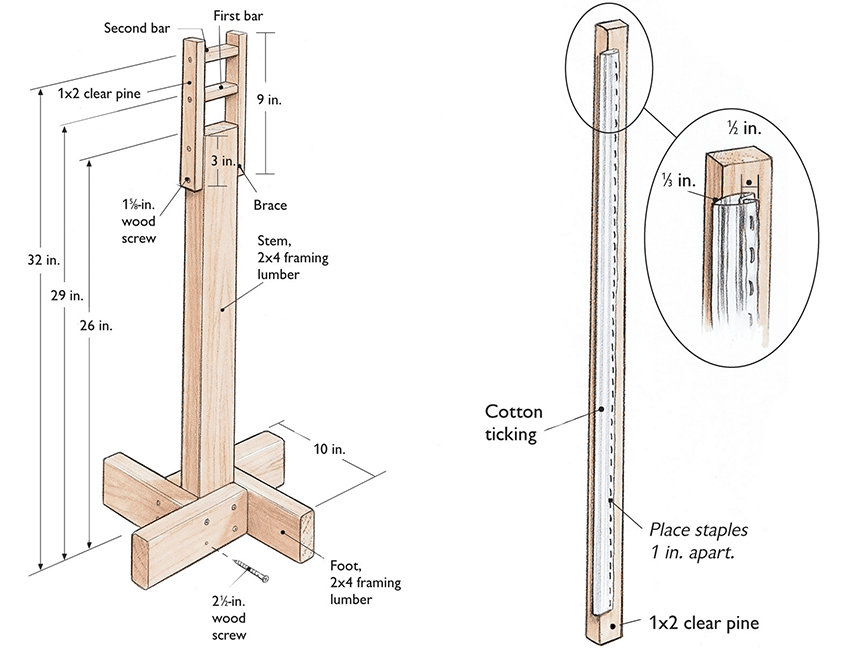

If you want to try a more inexpensive material, then you can always opt for wooden quilting frames. These frames are not only easy to make but also result in a frame that is sturdy and reliable to use.

To begin the project, you will first need to make sure that you have all the required material available. For this purpose, you will need pieces of wood. While you can use any type of wood, it is ideal that you use pine wood. You would also need a plywood board for the quilting frame. Baltic Birch Plywood is a great option for those looking.

The tools required for this quilting frame are simple and can be found at any hardware store. You would need:

Once you have all the tools and materials, you can get started. Here are the steps to achieve a perfect wooden quilting frame:

Step 1: The first thing you’ll need to do is to cut out your pine boards according to your desired size. Using a saw, cut out notches on your board to make a strong base for the frame. For this, you will need to cut a bottom notch on four boards and a top notch on the other four boards.

Step 2: After cutting, attach the boards together by clasping them together at the notches. You would need to make 4 bases of such type.

Step 3: Cut similar notches on the plywood board to help insert the bases. While cutting the notches, make sure that they are of the right size. Keep checking the size using a measuring tape and a marker. Once you are done, attach all the bases on the board.

Step 4: Next up, use a clamp or a tack to attach your fabric to the quilting frame. After attaching the fabric, you can start working on your quilt. You can either hand stitch the quilt or use a long arm quilting machine.

There you have it! You can now have your very own quilting frame plans by following the steps mentioned above. Making your own quilting frame might seem daunting at first but by now, you may have realized that it is not as difficult as it seems.

In fact, you can easily do it in the comfort of your home. You can now have DIY quilting frames while making sure that they are made for you to work comfortably. You can even customize your own personal touch on these quilting frames.

Longarm quilting is the process by which a longarm sewing machine is used to sew together a quilt top, quilt batting and quilt backing into a finished quilt. The longarm sewing machine frame typically ranges from 10 feet (about 3 meters) to 14 feet (about 4.25 meters) in length. A complete longarming system typically consists of an industrial length sewing machine head (19 – 30 inches,) a 10 to 14-foot frame, a table with a layer of plastic under which is placed a pantograph, and several rollers on which the fabric layers and batting are attached.

Polyvinyl chloride - WikipediaPolyvinyl chloride (colloquial: polyvinyl, vinyl; abbreviated: PVC) is the world’s third-most widely produced synthetic plastic polymer (after polyethylene and polypropylene). PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible.